Meet Mark Powders

Email: Mark.Powders@cdtwire.com

Academic and Industrial affiliations: Cranfield University, Northumbrian Water, Anglian Water, Severn Trent Water

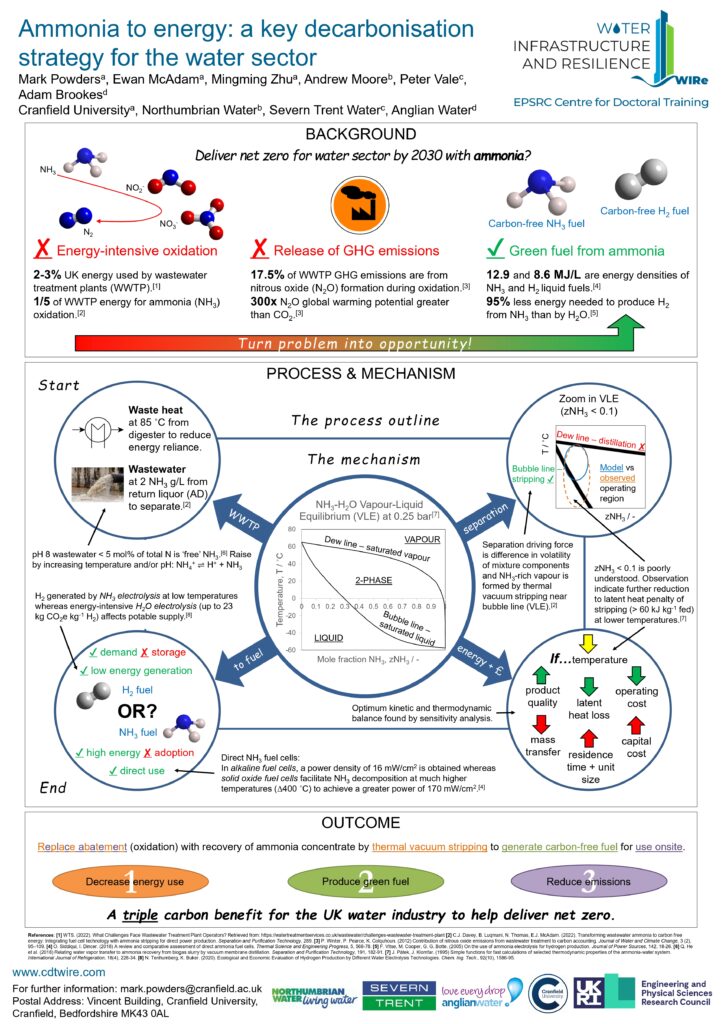

Title of research project: Ammonia to energy: A key decarbonisation strategy for the water sector

Treating the ammonia (NH3) present in wastewater prevents the eutrophication of aquatic ecosystems and lowers harmful emissions. Wastewater treatment plants convert NH3 to nitrogen in the presence of oxygen and microorganisms. However, the aeration required solely for NH3 treatment demands 1/5th of the treatment plant energy whilst collectively these plants consume nearly 3% of the UK’s total energy. Moreover, the nitrous oxide (N2O) generated as a by-product of treatment makes up over 15% of plant greenhouse gas emissions and has a global warming potential 300 times that of carbon dioxide. With the UK water sector committed to delivering a net-zero water supply by 2030, alternative treatment technologies with smaller greenhouse gas footprints are recognised as potential solutions. One such technology is the thermal vacuum stripping of NH3 from concentrated return liquor wastewater where NH3 is transferred from the liquid to vapour phase at low pressures. In this way, as much as 35% of NH3 in the plant is recovered as a valuable product rather than being abated using the conventional approach.

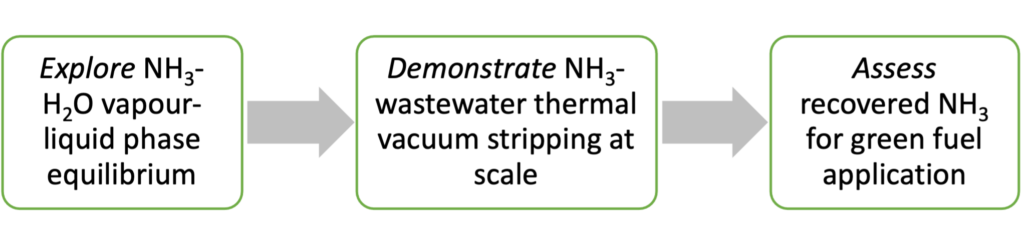

To develop thermal vacuum stripping for application in the water sector, this project will explore the poorly characterised vapour-liquid phase equilibrium compositions under vacuum pressure at low NH3-H2O concentrations. This knowledge better informs the design and operation of stripping units which are to be demonstrated from batch up to a larger scale continuous configuration. The project will also assess the unit techno-economic performance in relation to the quality of recovered NH3 product for green fuel application. Therefore, in addition to thermal vacuum stripping primary function of treating wastewater, using the recovered green fuel can reduce reliance on greenhouse gas emitting fossil energy powering the plant. Reliance is further diminished by decreasing energy-intensive aeration required during treatment which also consequently lowers N2O emissions.