Meet Thomas Langshaw

Email: tlangshaw1@sheffield.ac.uk

Academic and Industrial affiliations: The University of Sheffield, UKWIR

Title of research project: The insidious nature of pressure transients

A large portion of the UK’s water distribution network is still made up of cast iron pipes laid during the late 19th and early 20th century. These aging assets are, through a combination of continually varying loading and material loss due to corrosion, deteriorating. The deterioration can eventually initiate through-wall cracks and in turn leaks. Such leaks, although small, can contribute to a large volume of water loss due to the nature of being active for long periods or even indefinitely. One loading condition which can change rapidly is the internal pressure of the pipe. Termed pressure transients, these rapid internal pressure changes result from changes to the network conditions such as downstream flowrates. In recent years, the acknowledgement of how widespread and frequently pressure transients occur in water networks has led to the postulation that they can enable deterioration, specifically mechanical fatigue, during a pipe’s lifetime. Analysing the fatigue life of cast iron pipes is problematic due to mainly: i) these pipes were laid without consideration for fatigue in standards or design practice, ii) transient pressures and in turn stress histories, and corrosion rates of such pipes are largely unique to a specific pipe, iii) pipes are buried assets and routine inspection to monitor crack growth on any meaningful number of pipes would be infeasible.

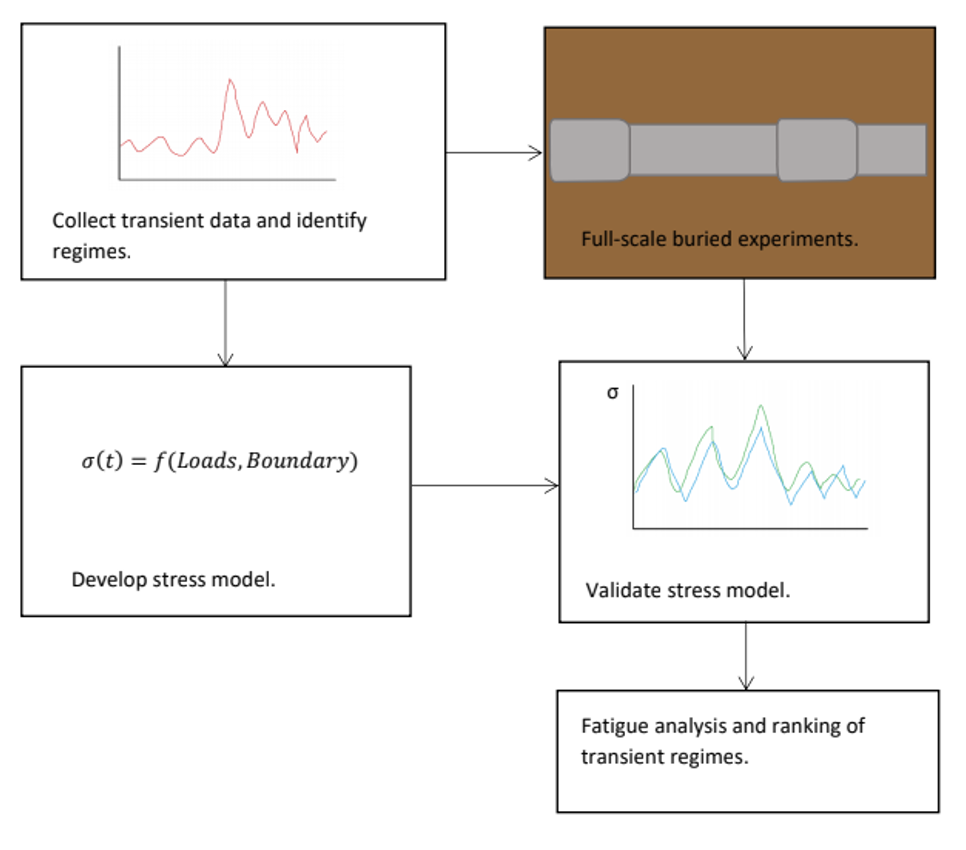

The project will use transient data recorded from UK water companies and identify transient regimes that can be linked to certain locations in water networks. To undertake a fatigue analysis of pipe lengths subjected to such transient regimes, a stress model which considers the external loadings and boundary conditions of a generalised cast iron pipe will be produced to give the temporal stress profile at a critical point on the pipe. The transient regimes will then be ranked in order of the fatigue damage they incur on cast iron pipes. Such information would enable water companies to focus mitigation activities upon areas where the most problematic regimes are found, thus increasing the effectiveness of asset management. By validating the stress model and subsequent fatigue analysis results against full-scale experiments and numerical modelling, conducting meaningful fatigue analysis of buried assets in the network could become a possibility in the future.