Meet Edward John

Email: Edward.john@cdtwire.com

Academic and Industrial affiliations: The University of Sheffield / UK Water Industry Research

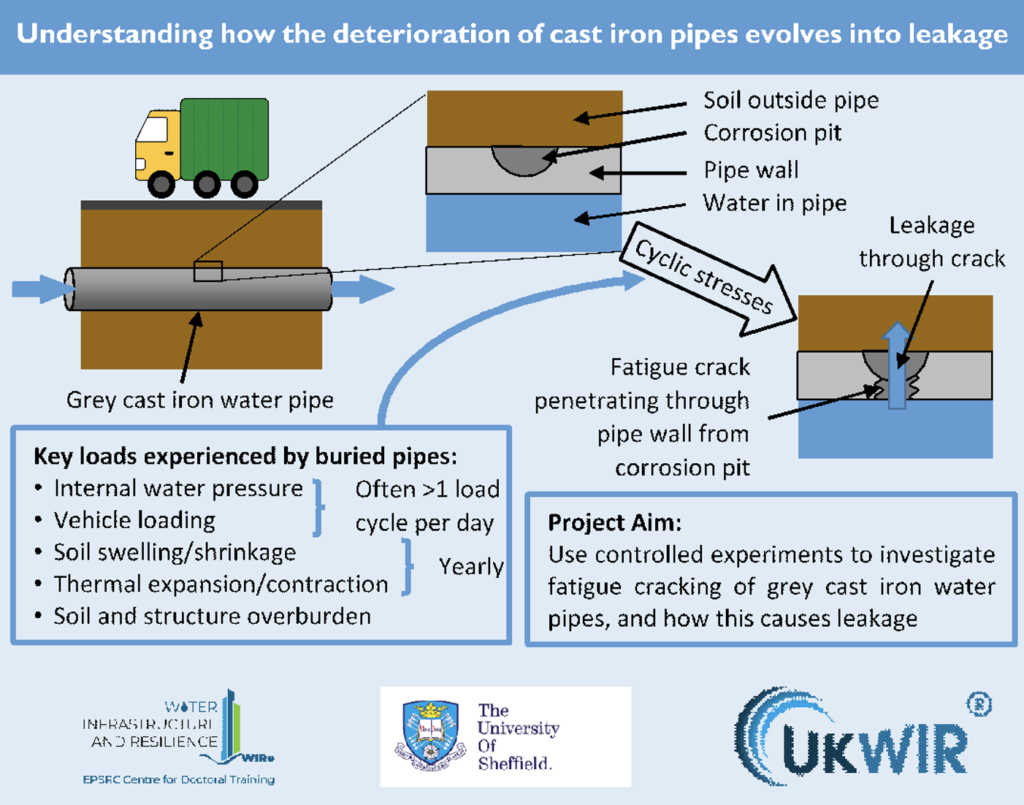

Title of research project: Understanding how the deterioration of cast iron pipes evolves into leakage

In the UK, around 22% of all drinking water produced is lost via leakage in the distribution system. A model that is able to predict how long after installation a pipe is likely to start leaking would enable pipe replacement programmes to target pipes that are predicted to be leaking, and therefore help reduce network leakage levels. However, a thorough understanding of the physical processes that cause a leak to initiate is required to create an accurate predictive model. The UK water distribution network contains pipes manufactured from a wide range of materials, and each material deteriorates and develops leaks in different ways. This project aims to identify and understand the mechanism by which leaking cracks form in the barrel of grey cast iron water pipes. These pipes were installed from the mid-1800’s up until the 1960’s and still make up a major part of many networks, but grey cast iron pipes also have some of the highest leakage and failure rates of all pipe materials making them a priority for investigation.

Buried water pipes are subject to an array of cyclic loads including: pressure transients, diurnal pressure variation, vehicle loading, soil swelling, and thermal contraction. Additionally, grey cast iron is highly vulnerable to corrosion by saline soils which can cause severe corrosion pitting of the external surface of a pipe, reducing the pipe’s wall thickness and creating stress concentrations. This combination of cyclic loading and geometric stress concentrators makes it highly likely that leaking cracks in pipe walls can form through a fatigue cracking process, however, this has not been confirmed by in-field or experimental observations. Therefore, this project aims to use highly controlled experiments to subject pipe specimens to cyclic loads representative of in-service conditions and observe how, and when, leaking fatigue cracks form, and what factors promote their formation.